Caratteristiche del nostro Macchina laser da 1000 watt

1. Stabilità e affidabilità del sistema del percorso ottico e del sistema di controllo

2. Laser in fibra originali importati, funzione alta e stabile, la durata della vita è di oltre 100000 ore

3. Maggiore qualità di taglio ed efficienza, la velocità di taglio è fino a 80 m/min con aspetto e bella tagliente

4. Riduttore, ingranaggio e cremagliera tedeschi ad alte prestazioni; guida giapponese e vite a ricircolo di sfere.

Industria applicabile e materiali di macchina da taglio laser a fibra

macchina da taglio laser a fibra applicazione:

taglio dei metalli, produzione di interruttori elettrici, aerospaziale, macchine alimentari, macchine tessili, macchine per l'ingegneria, produzione di locomotive, macchine agricole e forestali, produzione di ascensori, veicoli speciali, elettrodomestici, utensili, lavorazione, produzione IT, macchine petrolifere, macchine alimentari, utensili diamantati , saldatura, attrezzatura per saldatura, materiali metallici, pubblicità decorativa, trattamento superficiale laser di servizi di lavorazione esteri, come tutti i tipi di industria di lavorazione dei macchinari.

I nostri macchina da taglio laser a fibraMateriali di applicazione di:

Professionale utilizzato per tagliare lamiere sottili, in una varietà di taglio di lamiera di acciaio al carbonio di alta qualità da 0,5 -3 mm, può anche tagliare lamiere in acciaio inossidabile, lamiera in lega di alluminio, lamiera zincata, lamiera elettrolitica, acciaio al silicio, lega di titanio, lamiera di zinco alluminio e altro metallo.

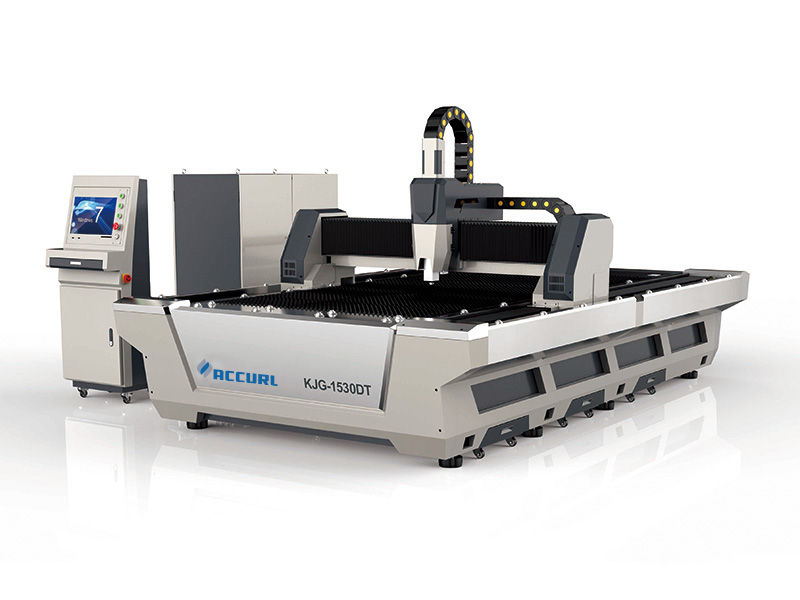

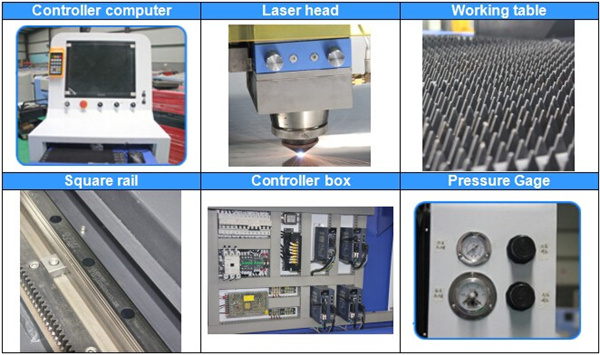

Principali immagini della macchina di Macchina da taglio laser da 1kw

Info Veloci

Applicazione: taglio laser

Condizioni: Nuovo

Tipo di laser: Laser a fibra

Materiale applicabile: metallo

Spessore di taglio: 0-20mm

Area di taglio: 1300 * 2500mm

Velocità di taglio: 25 m / min

CNC o no: Sì

Modalità di raffreddamento: raffreddamento ad acqua

Software di controllo: bechoff ( Cypcut )

Formato grafico supportato: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certificazione: CE, ISO, SGS

Servizio post-vendita fornito: ingegneri disponibili per la manutenzione di macchinari all'estero

Modello: laser da 1000 watt

Materiali da taglio: acciaio inossidabile acciaio al carbonio ecc. (Macchina da taglio laser per metallo)

Tipo di generatore laser in fibra: marca famosa Raycus (Made in China)

Testa di taglio laser in fibra: Lasermech (dagli Stati Uniti)

Motori e driver: servomotore Fuji da 1500 W prodotto in Giappone

min. Larghezza della linea: ±0.02mm

Vita lavorativa del modulo in fibra: più di 100000 ore

Tempo di garanzia: Tutta la macchina per 3 anni (fib

Parametro del nostro Tagliatrice laser a fibra

| Modello a macchina | 2500*1300mm |

| Potenza laser | 300W/500W/1000W/3000W |

| Tipo di generatore laser in fibra | Famoso marchio Raycus (Made in China) |

| Lunghezza d'onda del laser | 1064nm |

Qualità del raggio laser | <0.373mrad |

| Tavolo da lavoro | dente di sega |

| Testa di taglio laser in fibra | Lasermech (dagli Stati Uniti) |

| Obiettivo di messa a fuoco | Lasermech made in USA |

| Vita lavorativa del modulo in fibra | Più di 100000 ore |

| Motori e driver | Servomotore Fuji da 1500 W prodotto in Giappone |

| Reducer | 3 set dalla Germania |

| Rotaie di guida | Marchio PMI ad alta precisione di Taiwan |

| Sistema di trasmissione | Tipo a doppia cremagliera e pignone |

| Sistema a cremagliera | Germania rack |

| Sistema a catena | Igus made in Germany |

| Refrigeratore d'acqua | Marchio TEYU (S&A), CW6000 |

| Sistema di controllo | Sistema di controllo laser professionale--Cypcut

|

| Tipo di posizione | Punto Rosso |

| Spessore di taglio | ≤3mm (acciaio inossidabile) ≤6mm (acciaio al carbonio) |

| Massimo Velocità di marcia al minimo | 1400mm/s |

| Velocità di taglio | 300 millimetri / s |

| Precisione della posizione | ±0.05mm/m |

| Velocità di posizione | 20m / min |

| Min. Larghezza della linea | ± 0,02 millimetri |

| Consumo di energia | 12KW |

| Trasportare peso | 700KG |

| Voltaggio | 380V/50HZ, 3PH |

| Gas ausiliario per il taglio | Ossigeno, Azoto, Aria |

| Software compatibile | Autocad, Coreldraw, ecc |

| Formato grafico | Nc |

| Metodo di lavoro | Controllo da PC |

| Grado di protezione totale dell'alimentazione | IP54 |

| Peso della macchina | Circa 4000KG |

| Dimensioni della macchina | 4800*2600*1800mm |

| Tempo di garanzia | Macchina intera per 3 anni (modulo fibra 2 anni) |

Controllo di qualità del laser da 1000 watt

La qualità è il nostro più sincero rispetto offerto a tutti i nostri clienti ed è il fattore più importante per mantenere rapporti commerciali a lungo termine con noi.

Prestiamo sempre più attenzione alla qualità della macchina da taglio laser. Il sistema e il team di controllo della qualità standard sono responsabili di assicurare la qualità del prodotto in ogni processo con strumenti diversi come l'interferometro laser e il misuratore di potenza laser.

Nel processo di assemblaggio meccanico vengono utilizzati l'interferometro laser, il collimatore laser, l'indicatore a quadrante e la lastra di marmo; Nel processo di assemblaggio laser, vengono adottati il misuratore di potenza laser e il microscopio ottico.