applicazioni

Materiali di applicazione

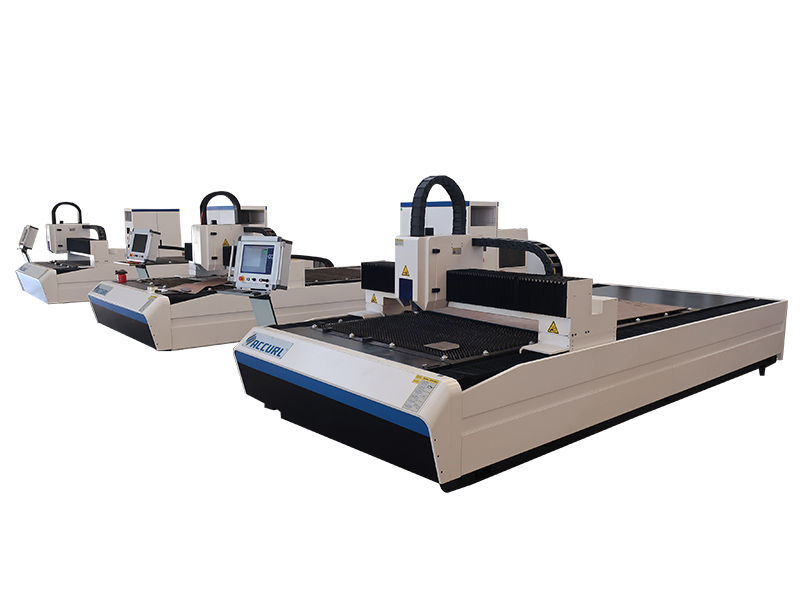

Attrezzatura per taglio laser a fibra è adatto per il taglio di metalli con lamiera di acciaio inossidabile, lamiera di acciaio dolce, lamiera di acciaio al carbonio, lamiera di acciaio legato, lamiera di acciaio per molle, lamiera di ferro, ferro zincato, lamiera zincata, lamiera di alluminio, lamiera di rame, lamiera di ottone, lamiera di bronzo, lamiera di oro, Piatto d'argento, piatto di titanio, lamiera, piastra di metallo, tubi e tubature, ecc

Settori applicativi

ACCURL Macchine per taglio laser a fibra sono ampiamente utilizzati nella produzione di tabelloni per le affissioni, pubblicità, insegne, segnaletica, lettere in metallo, lettere a LED, articoli per la cucina, lettere pubblicitarie, lavorazione della lamiera, componenti e parti in metallo, ferramenta, telaio, rack e armadi per la lavorazione, artigianato in metallo, oggetti d'arte in metallo, Taglio pannelli ascensore, Hardware, Ricambi auto, Montatura occhiali, Parti elettroniche, Targhette, ecc.

Descrizione del prodotto

• Caratteristiche

1. Basso costo:

Il tasso di conversione fotoelettrico è superiore al 30%, risparmiando energia e proteggendo così l'ambiente. La conversione fotoelettrica della macchina da taglio laser a fibra è 3 volte superiore alla macchina da taglio laser CO2

2. Eccellente qualità del raggio laser:

Il laser a fibra ha un diametro di messa a fuoco più piccolo e un'efficienza di lavoro più elevata, un'elevata precisione e qualità di taglio.

3. Alta precisione di taglio:

La precisione di posizionamento della taglierina laser a fibra è di 0,05 mm, la precisione di posizionamento ripetuta di 0,03 mm.

4. Funzionamento stabile:

Adottando i migliori laser in fibra di importazione mondiale, prestazioni stabili, le parti chiave possono raggiungere le 100.000 ore;

5. Eccellente effetto di taglio:

Il taglio senza contatto fa in modo che la rifilatura sia difficilmente intaccata dal calore, quindi nessuna deformazione termica del pezzo, nessuna necessità di una seconda lavorazione.

6. Risparmio di materiali:

La macchina adotta il software Cypcut. Utilizzando la programmazione del computer, è possibile tagliare diverse forme di prodotti, per massimizzare l'utilizzo dei materiali.

7. Operazioni facili:

Trasmissione in linea Fber, nessuna regolazione del percorso ottico;

8. Effetti ottici super flessibili:

Design compatto, requisiti di produzione compatti e facili da flessibili.

1. Letto della macchina

Il telaio della macchina più robusto garantisce un'elevata capacità di carico e nessuna deformazione facile.

L'effetto di taglio è altamente garantito e il tempo di servizio è più lungo.

2. Sistema di controllo

Con sistema Cypcut Control e software in lingua inglese, inserire file applicabili con DXF. O formato AI. Anche il disegno nel software va bene. Software con modalità di taglio al volo per tagliare gli stessi prodotti per risparmiare tempo. Con funzione Nesting, tipo di composizione autonomo per risparmiare materiali risparmiando spazi.

3. Sorgente laser in fibra

Sorgente laser Raycus 750W

La conversione fotoelettrica oltre il 30%;

Ambiente di lavoro: 10-40 gradi

Dispositivo con aria condizionata per mantenerlo a temperatura normale.

Durata: 100000 ore

4. Sistema di guida

Quattro set di motori di azionamento Panasonic giapponesi.

Abbinabile al sistema di trasmissione, migliora la velocità e la precisione di taglio.

5. Trasmissione ad ingranaggi

Sistema di trasmissione a cremagliera che con il marchio Taiwan Hiwin.

Asse X e Y La velocità di spostamento può essere max 80 m/min.

6. Sistema di raffreddamento

Quando la testa laser taglia i metalli, si produrrà dell'energia calda nella testa laser e nel dispositivo laser. Il refrigeratore d'acqua serve per raffreddare queste due parti. Parte della testa del laser, principalmente per il raffreddamento degli specchi.

La temperatura nel refrigeratore d'acqua è la regolazione automatica, impostata principalmente con 25 gradi intorno.

L'acqua nel refrigeratore dovrebbe essere acqua pura.

parametri tecnici

SPECIFICHE PER LXF-1530 macchina da taglio laser a fibra | |||

SORGENTE LASER | LASER DI RAYCUS | ||

TESTA DI TAGLIO | Testa di taglio famosa domestica della Cina | ||

MODALITÀ DI GUIDA | Motore passo-passo e driver Yaskawa | ||

TRASMISSIONE | Trasmissione ad ingranaggi | ||

GUIDA FERROVIARIA | Guide quadrate Hiwin | ||

RIDUTTORE | Importato dalla Francia | ||

REFRIGERATORE D'ACQUA | DOLUYO 1P | ||

SISTEMA DI CONTROLLO | CYPCUT da shanghai, Cina | ||

COMPUTER | COMPUTER INDUSTRIALE ADVANTECH | ||

REQUISITI DI POTENZA | TRIFASE AC 380V 50HZ | ||

PESO LORDO | 3.05MTS | ||

DIMENSIONI DI LAVORO | 3000*1500 MM | ||

Info Veloci

Applicazione: taglio laser

Condizioni: Nuovo

Tipo di laser: Laser a fibra

Materiale applicabile: metallo

Spessore di taglio: acciaio al carbonio 0-8mm

Area di taglio: 1500 * 3000mm

Velocità di taglio: 50 m/min

CNC o no: Sì

Modalità di raffreddamento: raffreddamento ad acqua

Software di controllo: sistema di controllo Cypcut

Formato grafico supportato: AI, DST, DWG, DXF, DXP, PLT

Luogo di origine: Anhui, Cina (continente)

Marchio: ACCURL

Numero di modello: LXF-1530

Certificazione: CE, ISO

Servizio post-vendita fornito: ingegneri disponibili per la manutenzione di macchinari all'estero

Potenza laser: 750W (opzionale 300, 500w, 1kw)

Area di lavoro: 1500 mm X 3000 mm (L/L)

Fonte di fibra: fonte di fibra Raycus

Tensione di lavoro: 380v 50hz a 3 fasi

Tavolo di lavoro: tavolo a dente di sega

Sistema di azionamento: servomotore giapponese YASKAWA

Risoluzione di riposizionamento: ±0,05 mm/m

Precisione di posizionamento assiale: ±0.04mm/m

Sistema di raffreddamento: refrigeratore d'acqua industriale 1.2P

Testa di taglio: marchio famoso in Cina